Introduction

Intermodal transportation is a reliable, sustainable method to ship freight at a reasonable cost. By definition, door-to-door intermodal leverages the efficiency of rail and the flexibility of truckload for a winning combination of price and service. The coming chapters will show how intermodal freight transportation can fit a variety of freight scenarios.

Chapters

Intermodal transportation involves a combination of road and rail - and a container. The Association of American Railroads (AAR) outlines the intermodal journey, which typically has product in an intermodal container driven via chassis-equipped dray truck to an intermodal ramp. The railroad then takes the container the long-haul portion of intermodal transport, before another dray truck takes it to its destination.

Types of intermodal transportation

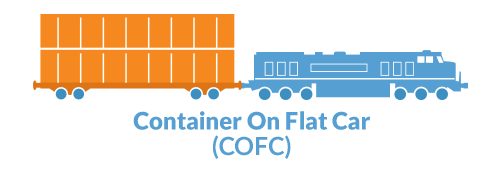

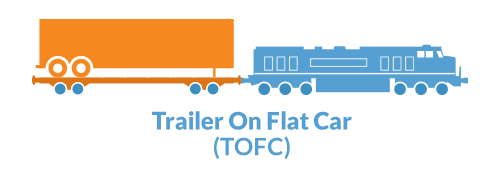

There are two types of intermodal: Container-On-Flatcar (COFC) and Trailer-On-Flatcar (TOFC). COFC, which came to prominence in 1984, is the most common and cost-effective because four containers can be loaded onto one wellcar. Under the TOFC model, the over-the-road (OTR) trailer is placed directly onto the wellcar - a maximum of two at a time.

Why is intermodal transportation so efficient?

Intermodal transportation offers a number of key efficiencies, including:

- Consistent railroad schedules with reliable service

- The energy efficiency (and consistency) of train combined with the flexibility of truck

- Significant capacity availability - up to 280 53-foot containers per train

- Constantly moving trains, sealed containers and secured ramps lead to low cargo theft risk

Through the 1950s, most goods were transported loose in small packages, known as break bulk. But that meant lengthy, laborious load-unload times, exposure to the elements and many lost packages. Then came containerized shipping, using metal shipping containers like those used by the military in WWII, capable of truck or train transport.

The modern intermodal industry was born. Soon after, standardized containers made intermodal the preferred method of international transport. In 1984, intermodal history was made again as 'double-stack rail transport' offered greater efficiencies.

Modern intermodal transport

Modern intermodal transport is an environmentally friendly and cost efficient way to move freight long distances. It can ship just about anything, with technology that supports tracking, security, refrigeration and more.

And while standard 53-foot boxes are the norm, ocean containers are another. Plus, domestic intermodal reliably covers all of North America.

Both intermodal freight transportation and over-the-road truckload shipping have their place within shippers’ logistics and supply chains. But you may be surprised which side wins in an intermodal vs. truckload comparison.

What are the advantages to using intermodal?

- Cost - For freight lanes that are a good fit for intermodal a shipper can expect to save 10% to 15% without sacrificing service.

- Sustainability - Railroad hauls grant intermodal a “leg up” in sustainability because railroads can transport freight 450 miles on only one gallon of fuel.

- Congestion - Intermodal avoids most congestion because it bypasses highway traffic, construction, and accidents - as the majority of the move is on rails.

- High value of freight - With an intermodal shipment, the train is always in motion at high speeds, only stopping at secured terminals with container status always tracked.

- Scalability - Intermodal trains can always carry more containers, and dray drivers can make several trips from the manufacturing facility to the railroad ramp.

- Length of haul - Intermodal provides a leveraged efficiency when the haul is over 700 miles. As the length of haul increases, rail becomes more efficient.

What are the advantages to using a truckload carrier?

- Origin and destination pairs - Truckload services are not held down to the location of intermodal ramps and inherently have the ability to pick-up and deliver to any location.

- Flexibility - Truckload shipments provide shippers a greater range of flexibility with access to shipments throughout transit and the ability to make alterations.

- Transit - Simply put, truckload is faster than intermodal, typically one to three days quicker depending on the lane and whether interlining occurs.

- Complexity - Truckload is the simplest way to move freight, as the shipper need only contact a single carrier to haul it - though an IMC offers a similar experience for intermodal.

- Weight - The weight restriction for intermodal is 2,500 pounds less than with truckload as the containers and chassis are heavier using intermodal.

- Length of haul - While intermodal wins for long-haul, truckload proves to be more beneficial for shorter distances due to the ease of pickup and delivery.

What is intermodal trucking?

Intermodal trucking - often referred to as drayage - involves trucks moving intermodal containers to and from rail ramps, making the door-to-door connection possible for intermodal freight. Without intermodal trucking, shippers would find it difficult to connect their loads with trains in most cases, severely limiting the viability of intermodal as an option.

Intermodal transportation has both advantages and disadvantages. But it's important to note that many of the perceived drawbacks - like slow transit or susceptibility to damage - are actually misconceptions or myths that need busting.

Transit times take too long - MYTH

The idea that intermodal transportation is “slow” comes from the moderate pace of traditional railcars. But railroads know their competition is truckload, so they deliver a much speedier product through intermodal service. Typical intermodal transit is truck plus one day - or plus two days when interlined. Some lanes are even equal.

It's unreliable - MYTH

Similar to the "slow" critique, many shippers unfamiliar with intermodal think railroad service makes it unreliable. However, intermodal freight lanes have on-time deliveries that rival or beat truckload because of the precision of rail transit schedules.

In fact, railroads have easily tracked transit times allowing for consistent planning over the long-term.

The market is small - MYTH

The truckload marketplace obviously has more players - roughly 700,000 for-hire-carriers compared to 10 main intermodal providers (with many smaller intermodal marketing companies (IMCs)). Those smaller IMCs provide flexibility in options and specializations - and even rates. Plus, federal agencies keep a close eye on rail industry pricing to ensure competition and prevent collusion.

Shipments are damaged or lost - MYTH

Contrary to some assumptions, your freight is no more open to damage or loss via intermodal than truckload. The unique element for rail cargo is harmonic vibrations. But the danger is only in not properly blocking and bracing to prevent shifting - damage prevention that oftentimes simply requires a couple of 2x4s and some nails.

It's too complicated - MYTH

There is a common misunderstanding that intermodal is operationally complicated, but while there are more steps in getting freight from A to B than truckload, an IMC allows shippers to make one call and receive one invoice, making the intermodal shipment process feel as simple as its over-the-road competitor.

In making the transition from an OTR (over-the-road) truckload solution, organizations always compare the cost of truckload to overall intermodal costs. The good news is, in most scenarios, intermodal transportation prices out significantly lower - anywhere from 10-25%. Pricing intermodal transportation consists of a familiar formula - linehaul plus fuel.

Also familiar to shippers are the three types of pricing for intermodal transport - contract, spot and project rates. It's key to understand each rate type and how to maintain the best mix as you develop the shipping strategy for your business.

Contract Pricing

Contract pricing is a rate promised by an intermodal service provider to move your freight on a set lane over a set period, usually a year. Contract pricing lets you lock in price and capacity - providing cost certainty and insurance against surges. The best time to negotiate is when volume is lower early in the year, and costs are based on projections.

Spot Rate Pricing

Contrary to contracts, spot rate pricing is negotiated when the shipper needs to move the freight. Because it's an immediate need, spot rates reflect the market at the time the request is made. Spot rates fluctuate day to day and even hour to hour based on seasonal patterns, weather, world events and various other external factors.

Project Pricing

Project pricing is meant for special projects. Special projects typically involve shipments with a volume outside of what would be considered the “norm” or expected quantities. Project pricing allows firms to take advantage of favorable prices over a shorter period of time because of volumes they can promise - though pricing depends on time of year.

While intermodal transportation may seem like it only fits specific scenarios, the right road and rail combination can fit a wide variety of shippers. Factors including distance (of the journey and between rail ramps), scheduling and value are worth considering.

Length of haul is at least 600 miles

The efficiency and strength of intermodal come into play when the freight move is 600 or more miles from origin to destination - allowing for economies of scale to take hold. It's important to note that intermodal can even be competitive with truckload for shipments of 450 miles if dray moves are near ramps.

Dray distance for intermodal ramps is no more than 100 miles

For a good intermodal lane, and to create the best road-to-rail conversion, a shipment should have dray lengths of 50 miles or less from the origin and destination ramps. That drayage distance though, can increase in either or both directions as the linehaul segment on the rail increases.

Shipment weight is 42,500 lbs or less

Weight and weight distribution are vital considerations for intermodal transport. While limits are the same for truckloads and intermodal containers, the heaviness of the chassis/container combo reduces the gross freight weight of an intermodal shipment by 2,500. Proper load configuration is also a must as both overweight and poorly distributed loads can face compliance issues and costs.

Transit can be scheduled one to two days earlier

Intermodal transit time is typically truck transit, plus a day when using a single railroad, and for intermodal shipments that are interlined, plus two days. So, if a shipment can be loaded one to two days earlier, then intermodal is an option. Those shippers who can plan ahead with a consistent schedule are rewarded.

High value shipments exceeding $100,000

Intermodal is especially beneficial for shippers moving high-value freight. Rail makes it far less likely for a shipment to be stolen because it is in constant motion with no easy way for an individual to get under the load to take possession. And when it stops, it's at secured ramps.

Meeting appointed loads or retail deliveries with short notice

Appointed loads or retail deliveries are another strength of intermodal as it can provide a high percentages of on-time deliveries. That's because it is not a one-to-one relationship like truckload. Instead, intermodal is a many-to-many relationship where rail can move large amounts simultaneously and multiple dray drivers can handle the rest.

Increased capacity beyond truckload

Intermodal can either provide additional capacity for those already using it or augment capacity requirements for truckload shippers. Dray capacity for drop and hook or live load/unload is quick and efficient - and available on short notice - because dray drivers can coordinate to turn several loads within a day for their short-distance trips.

Tracking protocols via lane visibility instead of GPS notifications

Shippers desiring increased lane visibility benefit from a tracking protocol similar to small parcel tracking, which offers opportunities to check the status of the shipment as it moves along the railway - versus pinging a GPS on a truckload shipment. The ability to “keep eyes everywhere” gives companies a competitive advantage managing their freight journey.

Selecting from diverse intermodal providers and types

There are many more intermodal providers than shippers often think, so do not fall into the trap to think there are only a few intermodal marketing companies. Not only are there more IMCs than many think, but there are various types, including:

- Bi-Modal - Also known as asset IMC, bi-modal IMCs own assets like containers, chassis and dray capacity - though the railroads own all train-related assets themselves.

- Asset-Lite - Asset-lite IMCs own just a few intermodal assets - often a limited amount of dray equipment

- Non-Asset - Non-asset providers own no intermodal assets, instead using those primarily of the Class 1 railroads and developing relationships with various dray companies.

- Rail Retailers - While U.S. Class 1 railroads cannot directly sell intermodal service, Canada does not have that prohibition, so Canadian National and CPKC do sell direct for north of the border loads

- Freight Brokers - Traditional freight brokers can offer intermodal service, though only through a registered IMC

If a shipment falls outside of traditional criteria that suggests a good intermodal fit, there are still a few options for shippers to implement intermodal into their logistics strategy.

- Transloading - The transfer of a shipment between freight modes is frequently used to move cargo from import containers to traditional intermodal boxes. This not only allows use of intermodal but also essentially makes every fourth shipment free.

- Consolidation - Consolidation occurs when smaller shipments normally slated for LTL shipping headed to the same location are bundled together under a single shipment - something intermodal can handle.

- Forward positioning inventory - A practice primarily in e-commerce, it supports just-in-time manufacturing. Intermodal is utilized to bulk stock the forward positioned warehouse locations to allow for speedy small-quantity customer deliveries.

Shippers who have made the decision to transition some or all truckload freight to intermodal should be mindful of a few keys to implementing this strategy successfully.

1. Select an IMC

The most important step to get off the intermodal starting line is choosing an IMC. The best intermodal companies are asset and non-asset, large and small providers, but it's no one-size-fits-all proposition.

At InTek, we're an IMC that works with class 1 railroads and dray providers across North America to deliver over-the-top service for our long-term shipper partners.

2. State your requirements

To determine intermodal requirements, shippers should prepare the following information for their IMC:

- Type of capacity required for either one-time all-in spot, project or contract rates

- Origin and destination zip codes

- Commodity

- List the beneficial cargo owner (BCO), in other words, who holds the title to the cargo

- Hazardous or non-hazardous cargo

- Live load and unload, drop container; build a drop pool of containers for larger volume lanes

- Volume

- Seasonality

- Temp-controlled

3. Obtain pricing

Once rate type is clear, send out an RFP (request for proposal) - casting a wide net for pricing as not all IMCs operate in the same lanes. You'll have to evaluate price vs service/reputation based on your initial selection.

4. Ship your goods

Once all requirements and pricing are set, the cargo is ready to move. That means the process of shipping an intermodal load begins:

- The shipper will tender the load to the IMC

- The IMC will coordinate to pick-up the freight load from the shipper’s dock and dray the load to the origin ramp

(There may be a point where the intermodal shipment must be weighed) - The container will be lifted off the chassis and loaded onto a rail wellcar

- The train of intermodal containers will be built and rail segment will begin

- Along the rail route, the container will pass various points where it will signal back its location for visibility

- Once at the destination ramp, the IMC will coordinate the dray pick-up and final delivery to the ultimate customer

5. Track your shipments

Each intermodal container has great visibility due to rail tracking along with sensors that indicate temperature and/or container opened status. InTek communicates these in real-time through a variety of technology.

6. Evaluate the outcome

After shipment, determine whether the outcome satisfied your goals related to cost, service-level and intact delivery. If not, get support and discuss corrective measures - the best IMCs will take these proactively. And keep evaluating each shipment for further improvements.

Implementing intermodal transportation can save money, improve reliability and help the environment. To incorporate intermodal into your shipping strategy, simply fill out our brief form, and one of our experts will help you get started with tailored solutions.